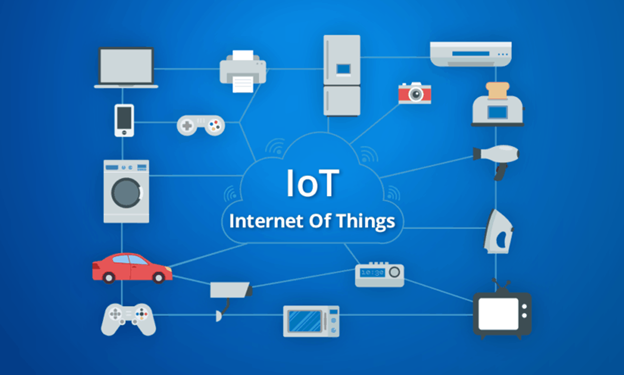

In today’s hyper-competitive manufacturing landscape, downtime is the enemy. Every second of unplanned machine failure results in lost output, reduced profit margins, and delayed market deliveries. According to Deloitte, industrial downtime costs manufacturers an estimated $50 billion annually. This is where the Internet of Things (IoT) becomes a game-changer, unlocking the full potential of predictive maintenance.

As manufacturing enterprises modernize their infrastructure, IoT-powered predictive maintenance is becoming one of the most strategic investments. It enables organizations to monitor asset health in real-time, predict equipment failure, and automate maintenance schedules before problems escalate.

What Is IoT-Driven Predictive Maintenance?

Predictive maintenance leverages smart IoT sensors, connected devices, and AI algorithms to collect machine data such as

- Temperature

- Pressure

- Vibration

- Acoustic patterns

- Energy consumption

- Humidity

- Load and torque

This real-time data is analyzed to detect abnormalities, identify wear patterns, and forecast possible malfunctions.

Instead of performing maintenance at fixed intervals, enterprises maintain equipment only when required, based on actual asset condition.

Why Manufacturers Are Adopting IoT for Predictive Maintenance

Adopting IoT solutions helps businesses:

✅ Reduce downtime by 30–50%

✅ Cut maintenance costs by up to 25%

✅ Increase asset lifespan

✅ Ensure worker safety

✅ Improve production efficiency

For industries with heavy machinery—like automotive, aerospace, mining, and chemical engineering—the impact is massive.

How IoT Predictive Maintenance Works: Step-by-Step

1. Data Collection via Smart Sensors

Sensors capture vibration, sound patterns, and temperature variations from machines.

2. Data Transmission

Data is transmitted to a cloud platform through protocols like MQTT, CoAP, or 5G.

3. AI-Driven Analysis

Machine learning models identify trends and detect anomalies.

4. Failure Prediction

The system predicts when components might fail—far in advance.

5. Automated Alerts

Technicians receive instant notifications on mobile dashboards.

6. Maintenance Scheduling

Service engineers can plan repairs during non-productive hours.

This eliminates guesswork and manual inspection cycles.

Key Technologies Powering Predictive Maintenance

To implement successful predictive maintenance, IoT integrates:

Edge computing for faster decision-making

Digital twins for real-time simulation

AI/ML algorithms for anomaly detection

Cloud analytics platforms (AWS IoT, Azure IoT, Google IoT Core)

Wireless communication like NB-IoT, LoRaWAN, 5G

Together, they enable powerful industrial automation.

Real-World Use Cases

1. Smart Factory Equipment Monitoring

Production machines are monitored 24/7 for:

- Bearing failures

- Motor overheating

- Shaft misalignment

- Lubrication issues

2. Predictive Maintenance in Mining

Heavy vehicles instrumented with IoT sensors predict engine wear and brake failures.

3. Oil & Gas Pipeline Monitoring

Sensors detect corrosion, leakage, and pressure fluctuations.

4. Energy Plant Turbine Monitoring

Vibration analytics prevent catastrophic turbine breakdown.

Advantages of IoT Predictive Maintenance

Reduced Repair Costs

Fixing small issues before failure avoids expensive replacement.

Improved Worker Safety

Machine failure hazards are minimized.

Longer Machine Lifespan

Optimal maintenance increases operational longevity.

Better Inventory Planning

Replacement parts are stocked based on prediction—not panic.

Higher Productivity

Less downtime means more output and revenue.

IoT vs. Traditional Maintenance Approaches

| Approach | Strategy | Drawback |

| Reactive | Fix after failure | Costly, dangerous |

| Preventive | Fixed schedule | Unnecessary repairs |

| Predictive (IoT) | Actual asset condition | Most efficient |

Predictive maintenance wins in performance, cost savings, and safety.

Industries Benefiting the Most

- Automotive manufacturing

- Power generation

- Pharma machinery

- Food & beverage factories

- Aviation & aerospace

- Chemical processing

Any industry with high-value assets can benefit.

Business Impact: ROI and KPIs

Enterprises measure value through:

Reduction in unscheduled downtime

Lower maintenance labor hours

Decreased spare part inventory cost

Increased Overall Equipment Effectiveness (OEE)

Better compliance and quality control

Most organizations witness ROI within 6–12 months.

Challenges and How IoT Solves Them

| Traditional Challenge | IoT Solution |

| Manual inspection errors | Sensor-based automated analysis |

| Unexpected failures | Real-time prediction |

| Costly downtime | Condition-based scheduling |

| Limited visibility | Cloud dashboards & alerts |

How an IoT Development Company Helps

A professional IoT development company provides:

IoT consulting & strategy

Sensor integration and hardware engineering

Predictive analytics using ML models

Custom mobile/web dashboards

Cloud enablement

Security implementation

Device lifecycle management

They ensure deployment scalability at industrial levels.

Security Considerations

IoT security is crucial. Companies implement:

- Encrypted data transfer

- Secure boot for devices

- Identity access management

- Firmware OTA updates

- Threat intrusion detection

Security ensures data integrity and equipment safety.

Future Trends Driving Adoption

AI-Optimized maintenance automation

Digital twins for simulation

Zero-touch device provisioning

5G-enabled ultra-low latency monitoring

Autonomous maintenance bots

Predictive maintenance is evolving toward full autonomy.

Conclusion

IoT-powered predictive maintenance is no longer optional—it’s a strategic necessity. Manufacturers who invest in connected asset monitoring gain:

- Reduced downtime

- Higher output quality

- Longer machine life

- Stronger safety metrics

- Better ROI

As competition intensifies, IoT adoption will differentiate industry leaders from laggards. Partnering with the right IoT development company ensures successful transformation, seamless deployment, and expert support throughout the asset lifecycle. With the future leaning toward autonomous smart factories, IoT predictive maintenance will remain central to Industry 4.0 success.